Our group focuses on employing and advancing the techniques in the field of computational solid mechanics through innovative approaches and interdisciplinary collaboration in order to address the plastic deformation, damage, and fracture phenomena in metallic materials at different length scales and under different types of loading conditions. We handle both fundamental challenges and real-world industrial problems with support from funding agencies and sponsor companies. Our focus is on delving into advanced numerical methods to address complex problems in solid mechanics, covering micromechanics, linear and nonlinear fracture mechanics, fatigue behavior, ductile damage and failure, and metal forming. We’re committed to developing efficient computational tools to enhance our understanding of how solids behave under different conditions. Our goal is to contribute to advancements in engineering design, manufacturing processes, and materials science.

Exploring the fundamental physics governing plastic deformation at the micro and meso scale is crucial for understanding the deformation and failure behavior of both single and polycrystalline macroscopic samples and structural components. The lab utilizes local crystal plasticity frameworks, along with higher and lower order strain gradient crystal plasticity models developed within our research, to address a variety of problems spanning different materials. For instance, understanding the dwell fatigue crack initiation and propagation in Titanium alloys, commonly used in gas turbine fan and compressor parts, necessitates  the application of accurate anisotropic plasticity modeling at the grain scale. The interaction between hard and soft grains can result in the formation of microcracks, posing a significant risk of catastrophic failures in aircraft engines. Another example is the formation of clear bands in steels under neutron irradiation in nuclear power plants. In these conditions, the material tends to become more brittle. Interestingly, irradiation-free regions emerge within the material, and plastic deformation becomes concentrated in these clear bands, potentially leading to the initiation of failure. The modeling of size effect and grain boundary misorientation dependent behavior in polycrystalline materials necessitates the use of appropriate strain gradient plasticity approaches, incorporating an internal length scale into the framework.

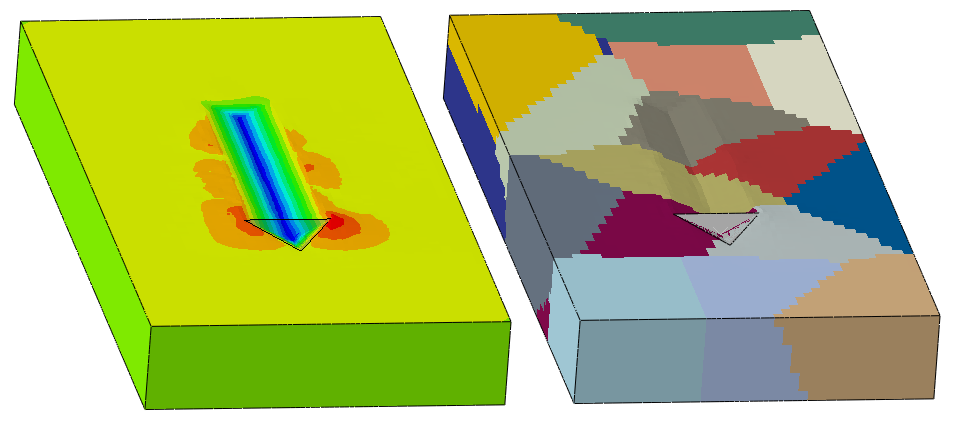

the application of accurate anisotropic plasticity modeling at the grain scale. The interaction between hard and soft grains can result in the formation of microcracks, posing a significant risk of catastrophic failures in aircraft engines. Another example is the formation of clear bands in steels under neutron irradiation in nuclear power plants. In these conditions, the material tends to become more brittle. Interestingly, irradiation-free regions emerge within the material, and plastic deformation becomes concentrated in these clear bands, potentially leading to the initiation of failure. The modeling of size effect and grain boundary misorientation dependent behavior in polycrystalline materials necessitates the use of appropriate strain gradient plasticity approaches, incorporating an internal length scale into the framework.  In utilizing the advantages of smaller grain size, severe plastic deformation processes have been developed to obtain ultra-fine grain structures, resulting in materials with significantly higher strength values. Micro plasticity models are instrumental in analyzing the deformation history and texture evolution during severe plastic deformation processes, such as twist extrusion and ECAP. These models effectively demonstrate the impact of imposed shear deformation on grain refinement. Recently, crystal plasticity modeling frameworks have been utilized for scratch hardness calculations during nano-scratching, and also for micro-machining various materials.

In utilizing the advantages of smaller grain size, severe plastic deformation processes have been developed to obtain ultra-fine grain structures, resulting in materials with significantly higher strength values. Micro plasticity models are instrumental in analyzing the deformation history and texture evolution during severe plastic deformation processes, such as twist extrusion and ECAP. These models effectively demonstrate the impact of imposed shear deformation on grain refinement. Recently, crystal plasticity modeling frameworks have been utilized for scratch hardness calculations during nano-scratching, and also for micro-machining various materials.

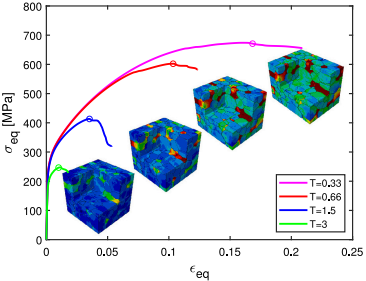

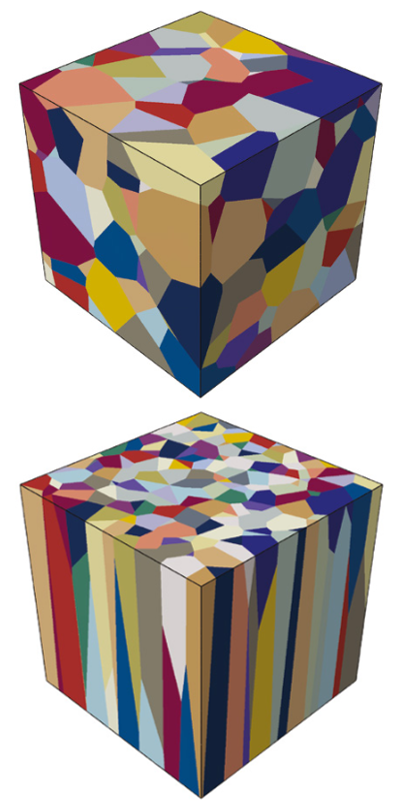

Beyond directly observing the impact of microstructural phenomena, micromechanical models are employed within a homogenization context to derive the macroscopic response. A notable example in this context is the development of anisotropic microstructures during additive manufacturing processes. The crystal plasticity approach is employed for each individual grain to capture crystallographic orientation-dependent behavior, as well as changes in grain shape and orientation grouping resulting from the manufacturing process. Another application involves investigating the influence of diverse microstructural parameters on macroscopic plastic deformation and initiation of degradation in two-phase materials, such as Dual-Phase (DP) steels. Modeling different phases with distinct material models, we achieve a macroscopic homogenized response that aligns with experimental material behavior through successful parameter identification. The influence of different triaxiality and Lode parameters are studied on the deformation and localization.

Beyond directly observing the impact of microstructural phenomena, micromechanical models are employed within a homogenization context to derive the macroscopic response. A notable example in this context is the development of anisotropic microstructures during additive manufacturing processes. The crystal plasticity approach is employed for each individual grain to capture crystallographic orientation-dependent behavior, as well as changes in grain shape and orientation grouping resulting from the manufacturing process. Another application involves investigating the influence of diverse microstructural parameters on macroscopic plastic deformation and initiation of degradation in two-phase materials, such as Dual-Phase (DP) steels. Modeling different phases with distinct material models, we achieve a macroscopic homogenized response that aligns with experimental material behavior through successful parameter identification. The influence of different triaxiality and Lode parameters are studied on the deformation and localization.

Our aim is on the development and advancement of predictive ductile and brittle fracture models, along with computational tools, to accurately assess the structural integrity and failure resistance of engineering components and materials. Through our research, we aim to advance understanding in fracture mechanics and provide solutions for enhancing the reliability and safety of critical structures.

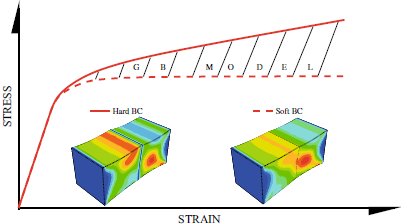

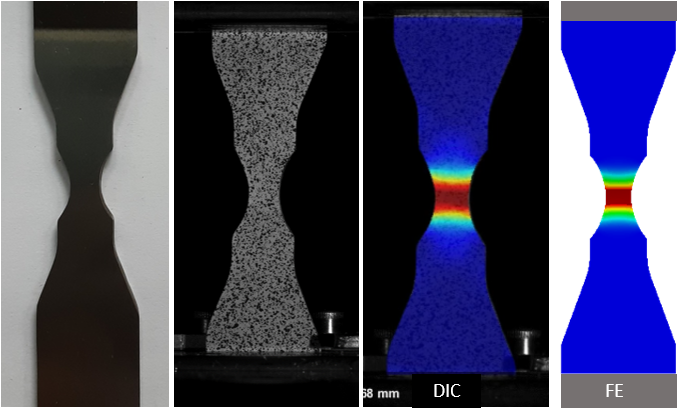

Fracture is intricately studied across various length scales, employing diverse methodologies tailored to address specific challenges. Cohesive zone models, extended finite element method (XFEM), and phase field fracture techniques have been used for different problems. Particularly in the realm of ductile materials, micromechanics-based cohesive zone models and porous plasticity models are developed in our group, effectively elucidating distinct failure mechanisms. Moreover, the widely used uncoupled and coupled damage models have been implemented, calibrated and applied for various processes, at both micro and macro scales, including material forming and ballistic impact.

Our aim is on the development and advancement of predictive ductile and brittle fracture models, along with computational tools, to accurately assess the structural integrity and failure resistance of engineering components and materials. Through our research, we aim to advance understanding in fracture mechanics and provide solutions for enhancing the reliability and safety of critical structures.

Fracture is intricately studied across various length scales, employing diverse methodologies tailored to address specific challenges. Cohesive zone models, extended finite element method (XFEM), and phase field fracture techniques have been used for different problems. Particularly in the realm of ductile materials, micromechanics-based cohesive zone models and porous plasticity models are developed in our group, effectively elucidating distinct failure mechanisms. Moreover, the widely used uncoupled and coupled damage models have been implemented, calibrated and applied for various processes, at both micro and macro scales, including material forming and ballistic impact.

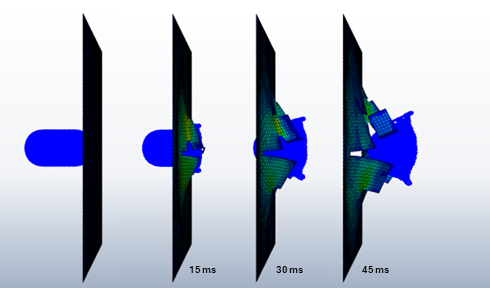

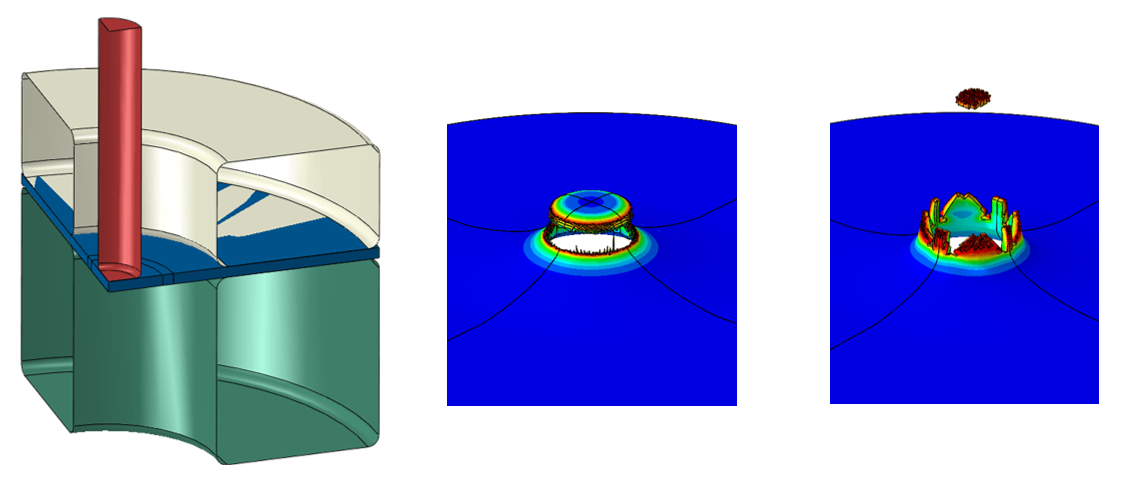

Our research group investigates the impact resistance of various materials under extreme loading conditions, focusing on ballistic impact and bird strike scenarios. In ballistic impact studies, we analyze the behavior of different metallic materials and single- or multi-layered plates subjected to high-velocity impacts from projectiles with varying nose shapes. These investigations aim to improve protective structures by assessing penetration resistance, energy absorption, and failure mechanisms. Additionally,

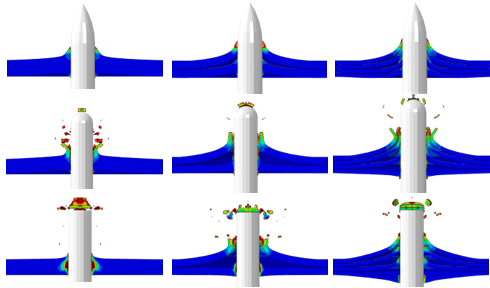

Our research group investigates the impact resistance of various materials under extreme loading conditions, focusing on ballistic impact and bird strike scenarios. In ballistic impact studies, we analyze the behavior of different metallic materials and single- or multi-layered plates subjected to high-velocity impacts from projectiles with varying nose shapes. These investigations aim to improve protective structures by assessing penetration resistance, energy absorption, and failure mechanisms. Additionally,  we study bird strike phenomena, particularly in aerospace applications. To accurately model these impacts, various tests, including dynamic mechanical analysis (DMA) and relaxation tests, have been conducted to calibrate the viscoelastic behavior of polymers, including polymethyl methacrylate (PMMA), which is widely used in aircraft canopies. By integrating advanced material models, our research provides valuable insights into the deformation and fracture behavior of metals and polymers, contributing to the development of more resilient aerospace structures.

we study bird strike phenomena, particularly in aerospace applications. To accurately model these impacts, various tests, including dynamic mechanical analysis (DMA) and relaxation tests, have been conducted to calibrate the viscoelastic behavior of polymers, including polymethyl methacrylate (PMMA), which is widely used in aircraft canopies. By integrating advanced material models, our research provides valuable insights into the deformation and fracture behavior of metals and polymers, contributing to the development of more resilient aerospace structures.

We are focused on exploring fatigue fracture phenomena in engineering materials, a crucial area with substantial implications for applications in aerospace structures and beyond. Our research examines the initiation and propagation of cracks under constant or variable cyclic loading conditions. Utilizing advanced techniques such as the Extended Finite Element Method (XFEM) and phase field fracture, our goal is to capture and gain insights into the intricacies of complex fatigue behaviors. We are particularly interested in exploring topics such as crack growth retardation under overload conditions; fatigue life under variable amplitude loading; and dwell fatigue. Titanium alloys used in aeroengines demonstrate vulnerability to dwell loading conditions, where a material is exposed to constant load periods during a fatigue cycle, directly leading to a reduction of several orders in the fatigue life. We actively collaborate with industry partners to translate our findings into practical solutions that enhance the durability and reliability of critical components subjected to fatigue conditions. Through our multifaceted approach, we aim to contribute significantly to the understanding and improvement of materials subjected to fatigue conditions in critical aerospace structures.

We are focused on exploring fatigue fracture phenomena in engineering materials, a crucial area with substantial implications for applications in aerospace structures and beyond. Our research examines the initiation and propagation of cracks under constant or variable cyclic loading conditions. Utilizing advanced techniques such as the Extended Finite Element Method (XFEM) and phase field fracture, our goal is to capture and gain insights into the intricacies of complex fatigue behaviors. We are particularly interested in exploring topics such as crack growth retardation under overload conditions; fatigue life under variable amplitude loading; and dwell fatigue. Titanium alloys used in aeroengines demonstrate vulnerability to dwell loading conditions, where a material is exposed to constant load periods during a fatigue cycle, directly leading to a reduction of several orders in the fatigue life. We actively collaborate with industry partners to translate our findings into practical solutions that enhance the durability and reliability of critical components subjected to fatigue conditions. Through our multifaceted approach, we aim to contribute significantly to the understanding and improvement of materials subjected to fatigue conditions in critical aerospace structures.

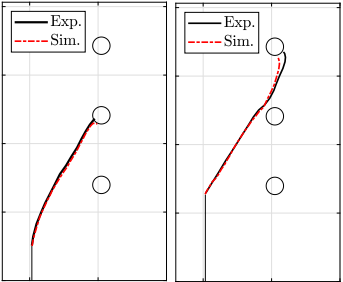

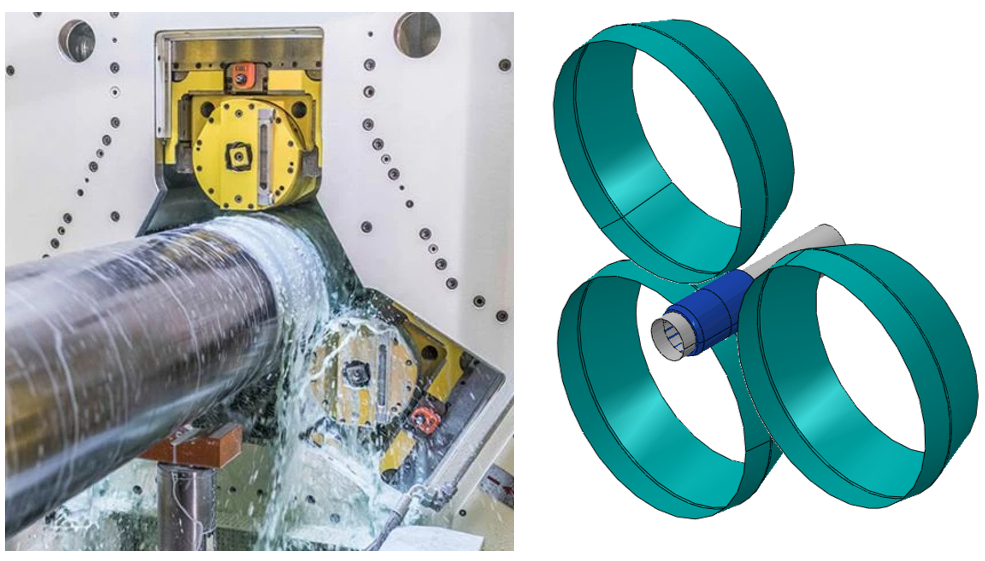

Within this domain, our research endeavors revolve around the development of computational models tailored to optimize metal forming processes, including flow forming, small punch, and incremental sheet forming. By leveraging computational tools, we aim to determine critical parameters such as formability and failure prediction in order to improve the effectiveness and reliability of the use of these processes in the production of metal parts, particularly in industries such as aerospace and defense.

Within this domain, our research endeavors revolve around the development of computational models tailored to optimize metal forming processes, including flow forming, small punch, and incremental sheet forming. By leveraging computational tools, we aim to determine critical parameters such as formability and failure prediction in order to improve the effectiveness and reliability of the use of these processes in the production of metal parts, particularly in industries such as aerospace and defense.  In collaboration with REPKON, our efforts are directed towards the refinement of the flow forming process, an advanced technique use to produce cylindrical parts with exceptional mechanical properties. Our research encompasses the development of a comprehensive finite element model, which accounts for thermo-mechanical effects, facilitating precise predictions of forming forces, final product geometry, and potential failure mechanisms.

In collaboration with REPKON, our efforts are directed towards the refinement of the flow forming process, an advanced technique use to produce cylindrical parts with exceptional mechanical properties. Our research encompasses the development of a comprehensive finite element model, which accounts for thermo-mechanical effects, facilitating precise predictions of forming forces, final product geometry, and potential failure mechanisms.

Our research group has recently focused on thermomechanical modeling and analysis of aero engine components under complex loading conditions in collaboration with TUSAŞ Engine Industries (TEI), one of Turkey’s largest companies specializing in the manufacturing of aeroengine components. This collaboration will address industry-specific challenges, including thermo-mechanical fatigue, creep, and creep-fatigue interaction. In aero engines, gas turbine blades withstand high temperature, pressure, and mechanical stress. Additionally, due to their high rotational speeds, turbine blades undergo the highest stress levels compared to other engine components from the consideration of both mechanical and thermal loads. This often leads to premature failure because of creep, oxidation, low-cycle fatigue (LCF) and high-cycle fatigue (HCF) phenomena. The primary objective of this collaboration is to study and model the aforementioned effects on the material and estimate the life of critical components of the aero engines.

Our research group has recently focused on thermomechanical modeling and analysis of aero engine components under complex loading conditions in collaboration with TUSAŞ Engine Industries (TEI), one of Turkey’s largest companies specializing in the manufacturing of aeroengine components. This collaboration will address industry-specific challenges, including thermo-mechanical fatigue, creep, and creep-fatigue interaction. In aero engines, gas turbine blades withstand high temperature, pressure, and mechanical stress. Additionally, due to their high rotational speeds, turbine blades undergo the highest stress levels compared to other engine components from the consideration of both mechanical and thermal loads. This often leads to premature failure because of creep, oxidation, low-cycle fatigue (LCF) and high-cycle fatigue (HCF) phenomena. The primary objective of this collaboration is to study and model the aforementioned effects on the material and estimate the life of critical components of the aero engines.

Our research focuses on hydrogen embrittlement and hydrogen-induced failure, which have emerged as critical and highly studied topics in solid mechanics in recent years. These phenomena arise when hydrogen atoms diffuse into a material’s lattice, leading to severe degradation in properties such as ductility, strength, and fracture toughness, and contributing to premature failure.

Our research focuses on hydrogen embrittlement and hydrogen-induced failure, which have emerged as critical and highly studied topics in solid mechanics in recent years. These phenomena arise when hydrogen atoms diffuse into a material’s lattice, leading to severe degradation in properties such as ductility, strength, and fracture toughness, and contributing to premature failure.  Our work spans both macroscopic and microscopic scales to achieve an understanding of these complex processes. At the macroscopic scale, we employ constitutive models, such as von Mises plasticity, to capture the overall mechanical response of materials under the influence of hydrogen. At the microscopic scale, polycrystalline microstructures are analyzed using representative volume elements (RVEs), and models like strain gradient crystal plasticity are applied to examine the role of microstructural features, such as grain boundaries and dislocations, in hydrogen-induced failure. This approach allows us to investigate key phenomena, including hydrogen diffusion, accumulation at grain boundaries, and how these processes weaken the material and lead to crack initiation and propagation. Our work aims to bridge the gap between microstructural mechanisms and macroscopic failure to provide a better understanding of hydrogen embrittlement.

Our work spans both macroscopic and microscopic scales to achieve an understanding of these complex processes. At the macroscopic scale, we employ constitutive models, such as von Mises plasticity, to capture the overall mechanical response of materials under the influence of hydrogen. At the microscopic scale, polycrystalline microstructures are analyzed using representative volume elements (RVEs), and models like strain gradient crystal plasticity are applied to examine the role of microstructural features, such as grain boundaries and dislocations, in hydrogen-induced failure. This approach allows us to investigate key phenomena, including hydrogen diffusion, accumulation at grain boundaries, and how these processes weaken the material and lead to crack initiation and propagation. Our work aims to bridge the gap between microstructural mechanisms and macroscopic failure to provide a better understanding of hydrogen embrittlement.